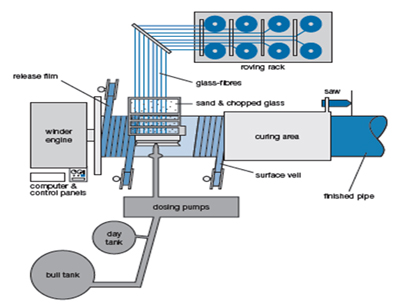

The GRP (glassfibre reinforced plastic) pipes are manufactured on highly sophisticated PLC controlled continuous filament winding (CFW) machine. The basic raw materials used are, fibre glass roving, polyester resin and silica sand.

The glass fibre laminate is applied onto a re-forming moving mandrel formed by continuous steel band over a horizontal beam provided with supporting disks size according to the diameter of pipe required.

Firstly the release film (polyester film) is wound on the mandrel followed by surface mat tissue, both of them supported by proper winder. Fibre glass roving together with chopped fibre glass, silica sand, polyester resin is applied simultaneously on the proper mandrel position according to design specification. At the end, a layer of surface mat tissue is applied.

After filament winding pipe is cured (polymerized). The process is basically exothermic (evolved the heat during reaction). After polymerization the pipe is cut to the desired length on a proper grinding and cutting machine.

Schematic diagram of CFW machine

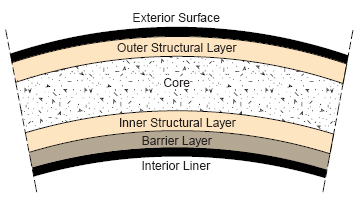

Cross Section of GRP Pipe

CFW machine

CFW machine producing φ 2600 mm pipe