GRP Pipes

GRP Fitting & Joints

Raw material Inspection

All the raw material is as per the national and international standards. Comply with standards material is accepted for pipe production

Dimensional and workmanship

Outside diameter, inside diameter, Thickness, length and workmanship is checked as per standards and comply with the design requirements.Hydro Test

The pipe is hydro tested for finding weeping, leakages of pipe wall. The hydro test is done at twice the pressure of pressure class of pipe as per standards.Stiffness Test

The stiffness of the pipe is determined at 5% vertical deflection for the specimen using Universal testing machine comply with the design of the pipe. The calculated stiffness complies with the design of the pipe.Beam Strength

The test is done to check the vertical load bearing capacity of pipe without failure complies with design of grp pipe and standards.Longitudinal Tensile Test

The test is done on the test piece cut from the pipe in longitudinal direction for checking the longitudinal tensile strength of the pipe. The calculated longitudinal tensile strength complies with design of grp pipe and standards.Hoop Tensile Test

The test is done on the test piece cut from the pipe in hoop direction for checking the longitudinal tensile strength of the pipe. The calculated longitudinal tensile strength complies with the design of grp pipe and standards.Type Test

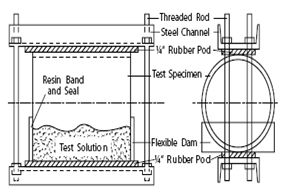

The following Type Tests are conducted on the pipe once in 3 year.1. Long Term Hydrostatic Test (HDB)

2. Potability of water (for potable water supply pipe)

3. Strain corrosion test (Sewerage, industrial waste & water other than potable pipe)